Custom Drop Stitch Floor – Complete Factory Guide

What is Drop Stitch Floor and How to Classify It

Definition of Drop Stitch Floor

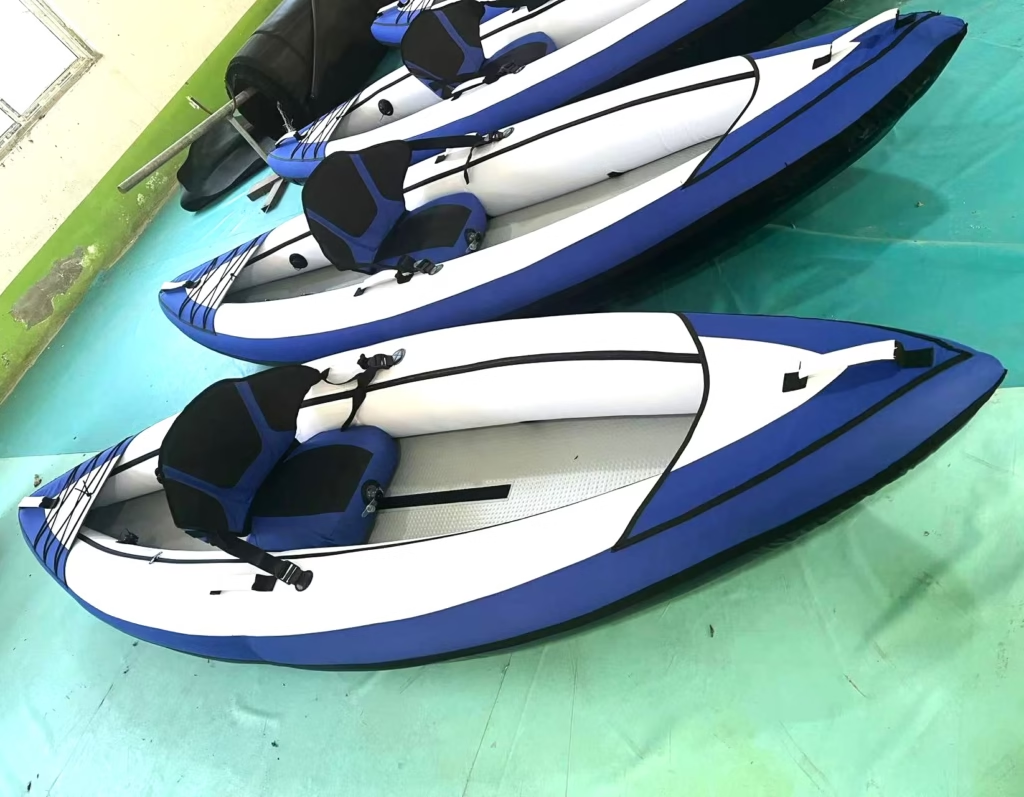

Drop stitch floor is a high-strength inflatable floor designed for kayaks and paddleboards. It combines rigidity with lightweight portability, providing paddlers with a stable and comfortable surface on water.

Drop stitch floors are designed for 1-person kayaks, 2-person kayaks, and 3-person kayaks, made from durable PVC or TPU with thicknesses of 0.7mm, 0.9mm, and 1.2mm. Each floor features heat-welded seams to ensure airtight performance and long-lasting durability, offering options from lightweight recreational use to heavy-duty commercial applications.

Craft and Texture

-

Craft: heat-welded for airtight performance

-

Texture: anti-slip, smooth, or patterned surfaces for safety and comfort

Drop Stitch Floor Applications

Drop stitch floors are versatile and used in various scenarios:

-

Inflatable Kayaks & Paddleboards: Provides firm, stable support for paddlers.

-

Water Sports & Recreational Activities: High-performance floors for surfing or leisure rides.

-

Camping & Outdoor Inflatable Equipment: Durable floors for tents or floating platforms.

Custom Drop Stitch Floor Production Process and Lead Time

Step 1 – Requirement Confirmation

Determine dimensions, material, color, and texture based on client specifications.

Step 2 – Sample Production

Create a prototype or sample for client approval, ensuring fit and quality.

Step 3 – Mass Production

Once the sample is approved, the factory proceeds with full production using high-quality materials and precise craft methods.

Step 4 – Packaging and Delivery

Finished floors are inspected, packed, and shipped directly from the factory.

Lead Time

-

Sample production: 7–14 days

-

Mass production: 20–30 days depending on quantity

How to Repair a Damaged Drop Stitch Floor

Common Damage Types

-

Punctures or holes

-

Surface scratches or abrasions

-

Weld seam separation

Repair Methods

-

PVC or TPU patching

-

Heat welding for seam repair

-

High-strength adhesive reinforcement

Maintenance Tips

-

Clean and dry after use

-

Avoid sharp objects or excessive pressure

-

Proper storage to extend lifespan

Reference video: repairing small holes on a single-person kayak.

Factory Advantages

Xsea factory specializes in custom drop stitch floor manufacturing, offering OEM solutions, high-quality materials, and precise production techniques.

-

Advanced production lines for large-scale manufacturing

-

Quality control at every step

-

Flexible customization for different client needs

CTA: Contact us today to request a quote for your custom drop stitch floor.